MFDC Spot Welder

Spot Welder

What is spot welding?

What is spot welding?

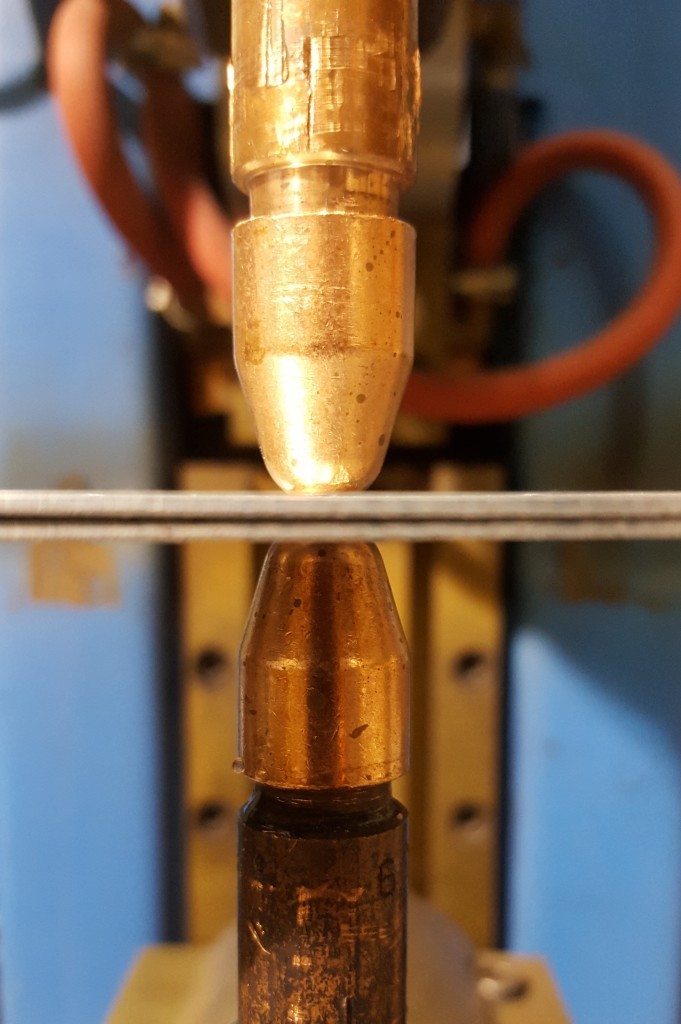

Spot welding basically joins two pieces of metal using the heat from an electric current. The two pieces of metal are pressed together with electrodes on either side. The electrodes are connected via a small spot. The current must be applied for the correct amount of time in order to get a strong join. The exact timing will depend on the types and thickness of metals being joined. Joining two pieces of metal together by spot welding is quick, easy and efficient.

Spot welding features

1. Spot welding is suitable for both similar & dissimilar workpieces and creates solid and long-lasting joints.

2. Uniformity in joints: Spot welding creates uniform joints while joining the workpieces with multiple weld spots. The same pressure and current through the electrode in each welding position result in uniformity. In addition, automatic or semi-automatic spot welding can be used to eliminate possible human error.

3. Joining of dissimilar materials: Spot welding can make strong, quality joints between dissimilar materials without distortion or warping. The only requirement is that the materials must be more electrically resistive than welding electrodes.

4. Cost Effective: Unlike other welding techniques, spot welding does not require inert gas, filler, or extra material, reducing the cost of consumables, and making welding more affordable. In addition, being energy efficient contributes to the lowering of welding costs.

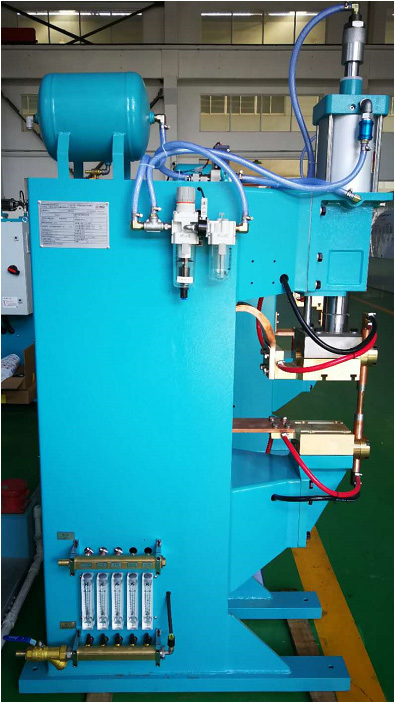

MFDC Spot Welder

MFDC stands for MID FREQUENCY DIRECT CURRENT.

MFDC stands for MID FREQUENCY DIRECT CURRENT.

Three phase AC @ 50 hertz input is converted to a high frequency 400-4000 Hz input to the transformer. The transformer then produces a DC output to the welder.

MFDC spot welder advantages

1. Three-phase power input, power factor up to 95%.

2. The requirement of welding current and pressure is lower, which helps save power.

3. High welding precision, short time, high efficiency, high production rate.

4. No need to use any fluxes or filler metal to create a join by spot welder.

5. The compact equipment structure requires small area, which saves installment cost of electric power, water, gas and so on.

6. Be performed without any special skill. Automatic welding process makes it easy to master the operation.

7. No dangerous open flame. Quite safe for the operator.

MFDC spot welder special functions

1. The MFDC spot welder is controlled by the man-machine interface microcomputer, and the welding specification program can be programmed and stored.

2. The welder has functions of grinding alarm, welding voltage real-time monitoring display, welding count, welding current over-limit alarm.

3. The welding controller has the function of fault self-diagnosis, welding voltage abnormal alarm, which reduces repair time.

4. Rapid current rise function, good current constancy, DC currency output for welding.

5. Spot welder can be applied to different metals to join.

6. It can be operated through automatic and manual type.

Weldable metals

Iron, carbon steel, stainless steel, galvanized steel, copper, brass, aluminium, nickel, tin, alloy, etc

Industries

Automotive, Aerospace, Architecture and Construction, Electrical and Electronics, Kitchenware, Hardware, Motor and Coil, etc.

Manufacturing and Repairing

Welded products

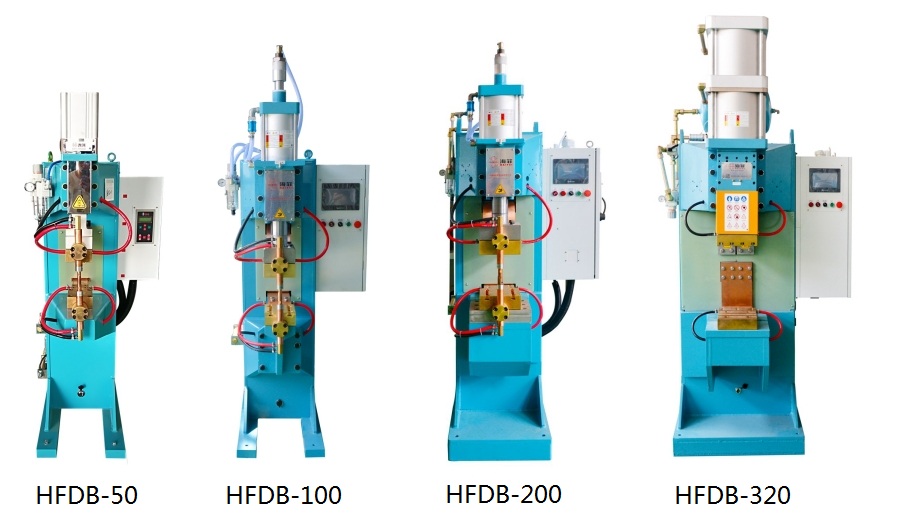

Specification and parameters

|

|

Items \ Model |

unit |

HFDB-50 |

HFDB-100 |

HFDB-200 |

HFDB-320 |

HFDB-440 |

HFDB-660 |

|

1 |

Rated capacity |

KVA |

80 |

160 |

240 |

320 |

440 |

660 |

|

2 |

Power supply |

V/Ø/Hz |

380V±10% / 3 phases / 50Hz |

|||||

|

3 |

Rated duty cycle |

% |

20% |

20% |

20% |

20% |

50% |

50% |

|

4 |

Primary current Max. |

A |

45 |

100 |

150 |

200 |

300 |

400 |

|

5 |

Primary cable |

mm2 |

3*16+2*6 |

3*25+2*16 |

3*50+2*16 |

3*70+2*16 |

3*90+2*16 |

3*135+2*16 |

|

6 |

Short-circuit current Max. |

KA |

18 |

38 |

58 |

76 |

100 |

120 |

|

7 |

Secondary voltage |

V |

9 |

9 |

9.6 |

12.5 |

12.5 |

12.5 |

|

8 |

Air pressure cylinder |

Ø*L |

Ø125*80 |

Ø160*120/ |

Ø160*120/ |

Ø200*120/ |

Ø200*120/ |

Ø200*120/ |

|

9 |

Working pressure Max. (0.5/10.5MPa) |

KN |

6 |

10/6 |

10/15 |

15/24 |

15/24 |

25 |

|

10 |

Cooling water demand |

/ |

0.2~0.3MPa,40 micron filtration, Resistivity of 5 kΩ. cm |

|||||

|

11 |

Cooling water consumption |

L/Min |

20 |

25 |

35 |

50 |

50 |

50 |

|

12 |

Throat depth |

mm |

460 |

425 |

425 |

380 |

380 |

425 |

|

13 |

Distance between copper plates |

mm |

208 |

248 |

248 |

320 |

/ |

/ |

|

14 |

Working environment |

|

temperature: 1~45℃ humidity: 35~90% |

|||||

Key words:

MFDC Spot Welder

More Content

Get a Free Product Quote

If you are interested in our products, please leave your contact information and we will dispatch experts to communicate with you within 24 hours.

Language

Language