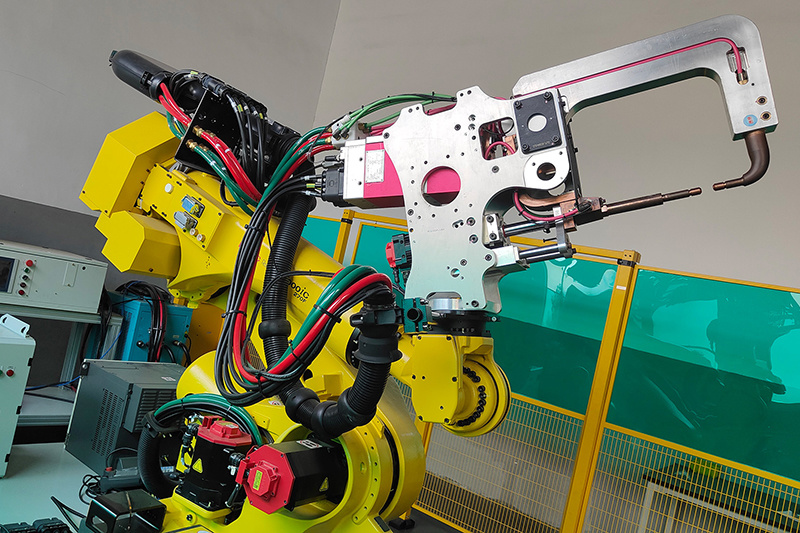

Robotic Welding Workstation

Robotic spot welding systems are particularly useful for welding thin sheets of metal, such as those used in the automotive industry for car body assembly. They are capable of producing high-quality welds quickly and consistently, making them ideal for high-volume production environments.

In a typical spot welding operation, the robotic arm positions the welding electrodes on the workpieces and applies pressure. The power supply then delivers a high-current, low-voltage electric pulse, which generates heat and causes the workpieces to melt and fuse together at the spot. The duration of the electric pulse, known as the weld time, is typically in the order of milliseconds, and it is a critical parameter that affects the quality of the weld.

|

|

Robotic spot welding systems offer exceptional precision and repeatability, ensuring consistent weld quality across production lines. These systems are extensively used in the automotive industry, where they provide efficient and reliable joining of car body panels, frames, and other metal components.

The automation of spot welding not only enhances productivity but also enables superior control over process parameters, contributing to the overall strength and durability of the welds.

Get a quoteKey words:

Robotic Welding Workstation

More Content

Get a Free Product Quote

If you are interested in our products, please leave your contact information and we will dispatch experts to communicate with you within 24 hours.

Language

Language