What is resistance welding? [RW01]

Dec 13,2023

What is resistance welding? [RW01]

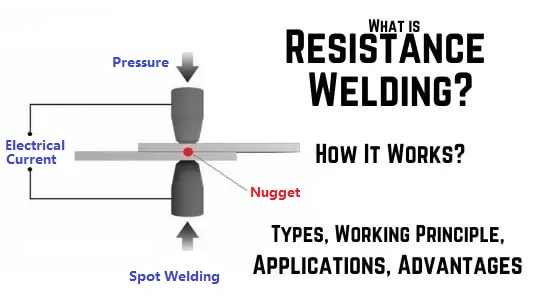

Resistance welding is a type of electric welding which involves heating metal by a powerful electric current and applying pressure or tension to join two pieces of metal together.

The resistance welding process does not require high temperatures and hence it allows for the welding of soft materials such as copper, aluminum, brass, nickel, etc.

It is a fast and cost-effective method for joining metals, widely used in high-volume production on metal parts.

The process of resistance spot welding involves the use of specialized equipment, including welding electrodes and a power supply. The electrodes apply pressure to the metal sheets while passing a high electrical current through them, generating heat at the contact points. As the metal reaches its melting point, the electrodes exert pressure, causing the molten metal to fuse, ultimately forming a solid weld nugget. This seamless fusion results in welds with excellent mechanical properties, making resistance spot welding a preferred choice in industries that demand reliable and high-strength joints.

Applications

Resistance welding finds widespread applications across various industries, ranging from automotive and aerospace to consumer electronics and appliance manufacturing. In the automotive sector, resistance spot welding is extensively used to assemble car bodies, joining metal panels and components with precision and durability. This process plays a crucial role in enhancing the structural integrity of vehicles, contributing to their safety and performance.

In the aerospace industry, resistance welding is employed for fabricating aircraft structures and components, where high-strength and reliable welds are essential for ensuring the safety and longevity of aircraft. The versatility of resistance welding also extends to the consumer electronics and appliance manufacturing sectors, where it is utilized for joining metal enclosures, frames, and components with efficiency and consistency.

Features and Advantages of Resistance Welding

- Generally no flux such as solder or welding rod is necessary. Welded parts can be easily recycled.

- High speed and very short time of welding enables high production rate. Quite suitable for massive production of low-cost products.

- Workpieces hold their original appearance at welding area to a big extent.

- Welding condition and parameters setting must be prepared necessarily. Optimum welding parameters must be figured out before actual welding.

- Easy operation of automation weld process. No need of trained skills like arc welding and gas welding.

- Safe, clean and environmentally friendly to operator due to low voltage.

Related News

Language

Language